Cable plough from FOECK | Laying pipes and cables without trenches

Gewinner des Exportpreises Bayern 2022, Laudator Dr. Georg Haber und der Staatssekretär im Bayerischen Staatsministerium für Wirtschaft, Landesentwicklung und Energie, Herr Roland Weigert überrreichten den Preis.

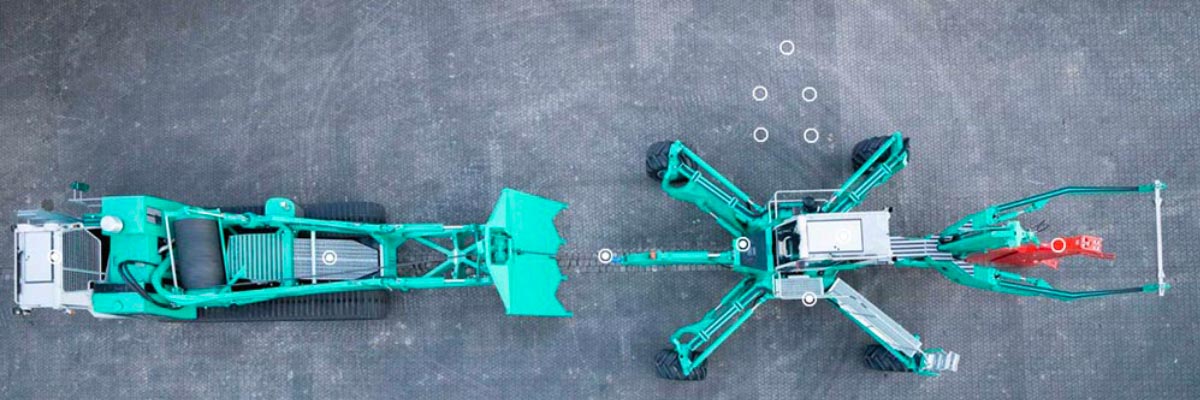

Machines for infrastructure construction

From fibre optics to Ø630mm pipes

For all soil conditions (sand, gravel, moor and through water)

For more than 65 years we have been developing machines and systems for trenchless laying of cables and pipes. We produce cable ploughs, spider ploughs, cable winch vehicles and mobile tractors in highest quality.

To date, more than 450,000 kilometres of cables and pipes have been laid worldwide with our systems.

The benefits in one view

- Innovative system for trenchless pipe and cable laying

- The world market leader in the field of trenchless pipe and cable laying

- The world's strongest winch and laying-plough systems with up to 360 tonnes of tractive force

- Used on every continent and on any terrain

- Incredible performance: 10.000 metres per day and a maximum pipe diameter of 630 mm

- Ecological and sustainable – no trench, minimum impact on the natural environment

Our cable ploughs in action for you

![[Translate to Englisch:] Walter Föckersperger](/fileadmin/media/home/Walter-Foeckersperger.jpg)

We are pleased to advise you

Would you like to learn more about the FOECK laying system? Then we look forward to hearing from you by phone, e-mail or via our contact form. You are also welcome to arrange a consultation with us in which we present technical details of our products.

Walter Föckersperger, Managing Director

Phone: +49(0) 8742 43897-0

Mail: walter.foeckersperger@foeck.com

What characterises our products:

Efficient laying ploughs for all ground conditions

Efficient laying ploughs for all ground conditions

Whether underground cables, power lines, high-voltage lines, water pipes, sewage pipes, gas lines or fibre optic cables for broadband expansion - we offer the right machine for all ploughing work. And we are equipped accordingly for different soils: Mud, sand, water, gravelly, hard soils and other soil conditions are no problem for our ploughing machines.

Cable ploughs and winch vehicles of different strengths

In our product range you will find the FSP6 cable plough, a small and agile plough. The FSP22 cable plough is used for a wide range of applications. For pipes and cables up to 630 mm we recommend our FSP280. The FWF50 is designed as a cable winch vehicle with a tractive force of 50 tons. Our FWF 80 has a pulling force of 80 tons and the FWF 93 Crawler 90 tons.

Customer Support

Services around the FOECK laying system

Today, the FOECK laying system is one of the most efficient methods of laying pipes and cables safely and quickly in the ground. For this purpose we offer not only the most efficient laying machines but also a comprehensive range of services...

Cable plough videos

Voice of the customers

![[Translate to Englisch:] Walter Föckersperger](/fileadmin/media/home/Walter-Foeckersperger.jpg)

We are pleased to advise you

Would you like to learn more about the FOECK laying system? Then we look forward to hearing from you by phone, e-mail or via our contact form. You are also welcome to arrange a consultation with us in which we present technical details of our products.

Walter Föckersperger, Managing Director

Phone: +49(0) 8742 43897-0

Mail: walter.foeckersperger@foeck.com

These customers trust in the FOECK laying system

![[Translate to Englisch:] European Utility Ploughing Specialists](/fileadmin/media/start/European-Utility-Ploughing-Specialists.jpg)

![[Translate to Englisch:] IFK-Verlegepflug](/fileadmin/media/start/IFK-Verlegepflug.jpg)

![[Translate to Englisch:] Rühlmann Bau](/fileadmin/media/Referenzen/Ruehlmann-Bau.jpg)

![[Translate to Englisch:] cendrawasih](/fileadmin/media/start/cendrawasih_logo.jpeg)

![[Translate to Englisch:] RKE](/fileadmin/media/start/RKE_Logo.jpeg)

![[Translate to Englisch:] RCS](/fileadmin/media/start/rcs_logo.jpeg)

![[Translate to Englisch:] Thomasen Anlagenbau](/fileadmin/media/start/Thomsen-Anlagenbau.jpeg)

![[Translate to Englisch:] Josef Schnell](/fileadmin/media/Referenzen/Josef-Schnell.jpg)

![[Translate to Englisch:] Spider Plow](/fileadmin/media/start/Spieder-Plow.jpeg)

![[Translate to Englisch:] WPD](/fileadmin/media/start/wpd_logo.jpeg)

![[Translate to Englisch:] ITS](/fileadmin/media/start/its.jpeg)

![[Translate to Englisch:] Pflugverfahren Kabelpflug](/fileadmin/media/FSP6.jpg)

![[Translate to Englisch:] Pflugverfahren Kabelpflug](/fileadmin/media/FSP22.jpg)

![[Translate to Englisch:] Pflugverfahren Kabelpflug](/fileadmin/media/FSP220.jpg)

![[Translate to Englisch:] FWF 50 Die kleine mobile Seilwinde mit 50 t Zugkraft](/fileadmin/media/FWF50.jpg)

![[Translate to Englisch:] FWF 80 Die starke mobile Seilwinde mit 80 t Zugkraft](/fileadmin/media/FWF80.jpg)

![[Translate to Englisch:] FWF 92 / Crawler Die stärkste mobile Seilwinde mit 90 t Zugkraft](/fileadmin/media/FWF92.jpg)

Our company, Innovative Trenching Solutions Ltd. (“ITS”) owns and operates the Föckersperger (“FOECK”) plough and winch equipment all over Canada and the United States of America. Our talented team has been working with the FOECK group and their equipment for many years, which shows our trust and support in the FOECK brand. ITS is a strong advocate of the FOECK equipment because it is engineered very safely, effectively, and environmentally friendly for almost all underground utilities. We highly recommend for you to consider utilizing the FOECK equipment on your next project.

Samil Junuzovic, General Manager ITS

“Machinery you cannot find anywhere else in the world with excellent after sales service. The FOECK brand has innovation and product development embedded in its DNA. It is a privilege to collaborate with FOECK on our project requirements”.

Ben James, Operations Manager, ATP