Advantages of the FOECK laying plough - it is worth ploughing!

For local authorities and planners, it is often difficult to lay supply lines without considerable impact on the natural environment. The FOECK laying plough, however, provides a reliable solution.

"Lay cables and pipes wherever they are needed."

One of the advantages of the laying plough technology is that there is generally no need for preparatory work which damages the natural environment (such as stripping topsoil or removing trees and bushes). No soil is dug out, which means that changes to the ground structure and subsequent compaction are avoided.

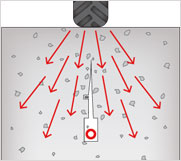

During open construction – with a rotary hoe or excavator – stones, which fall onto the pipe as the trench is being filled, exert a bearing pressure which can be up to 4 times the permissible value onto the pipe, due to the mass of earth above (in the case of a stone with a diameter of 5 cm, the mass of the earth above is approximately 6 kg).

The mechanical or independent compaction (setting) of the soil (right) results in deformation of the pipe. As a result, a pipe fracture is often inevitable.

During no-dig construction (image), the laid cable/pipe rests freely and relaxed on the base of the slot after it has been laid with the plough. When the surface is restored, the laying slot is closed almost halfway from the top. The ground forms a bridge over the laid cable/pipe. Even if stones fall in, they cannot damage the cable/pipe. They simply rest on the pipe under their own weight. This supporting bridge now protects the laid cable/pipe. Even if the heaviest vehicles drive across the laying slot, the laid cable/pipe will not be affected. A sand bed is not required.

The laying plough draws a narrow slot in the ground in a single step with the aid of a cable winch. At the same time, one or more cables/pipes can be safety laid on the smoothed base of the slot.

Depending on the number and size, the cable drums are also carried along on the plough. After the laying process, the narrow slot closes almost by itself and provides long-lasting protection for the cable or pipe, see above.

Cables and pipes belong underground

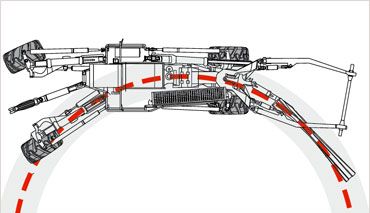

The landscape needs to be protected as well as the material to be laid. Once the FOECK laying plough, also called a cable plough or SpiderPlow, has finished its work, only a specialist is able to tell what working procedure has been carried out here. With hardly any restoration work, it is not possible to tell what work has been done on the laying section at a depth of up to 2.5 m in the ground in an incredibly short space of time. In addition to its manoeuvrability, the plough also impresses with its cross-country mobility. With its wheel arms which can be adjusted on all sides, it can adjust its wheels vertically so that it can plough slopes upright up to 45 degrees, the wheel arms can also be adjusted horizontally up to 6.50 m. This allows it to travel over ditches, pits and so on. With the laying plough, a turning radius of up to 4 m can be realised (see image to the right). It can be used practically everywhere, on slopes, in forests, close to trees, bushes and hedges, on escarpment, behind and across crash barriers, next to tarred road surfaces, through streams and rivers as well as on wetlands through marshland areas.

![[Translate to Englisch:] Verlegeverfahren nach EN 1610](/fileadmin/_processed_/2/2/csm_LWL_6_1_c7c9cdf60f.jpg)

Laying process according to EN 1610

The ploughing of lines with the FOECK laying plough is an automated laying procedure in the sense of the final draft of the European Standard EN 1610 – i.e. it is a state-of-the-art laying process, according to regulations.

![[Translate to Englisch:] Verlege Anwendung und Nutzen](/fileadmin/media/verlegesystem/Syst_Verlege_Anwend_Nutzen.jpg)